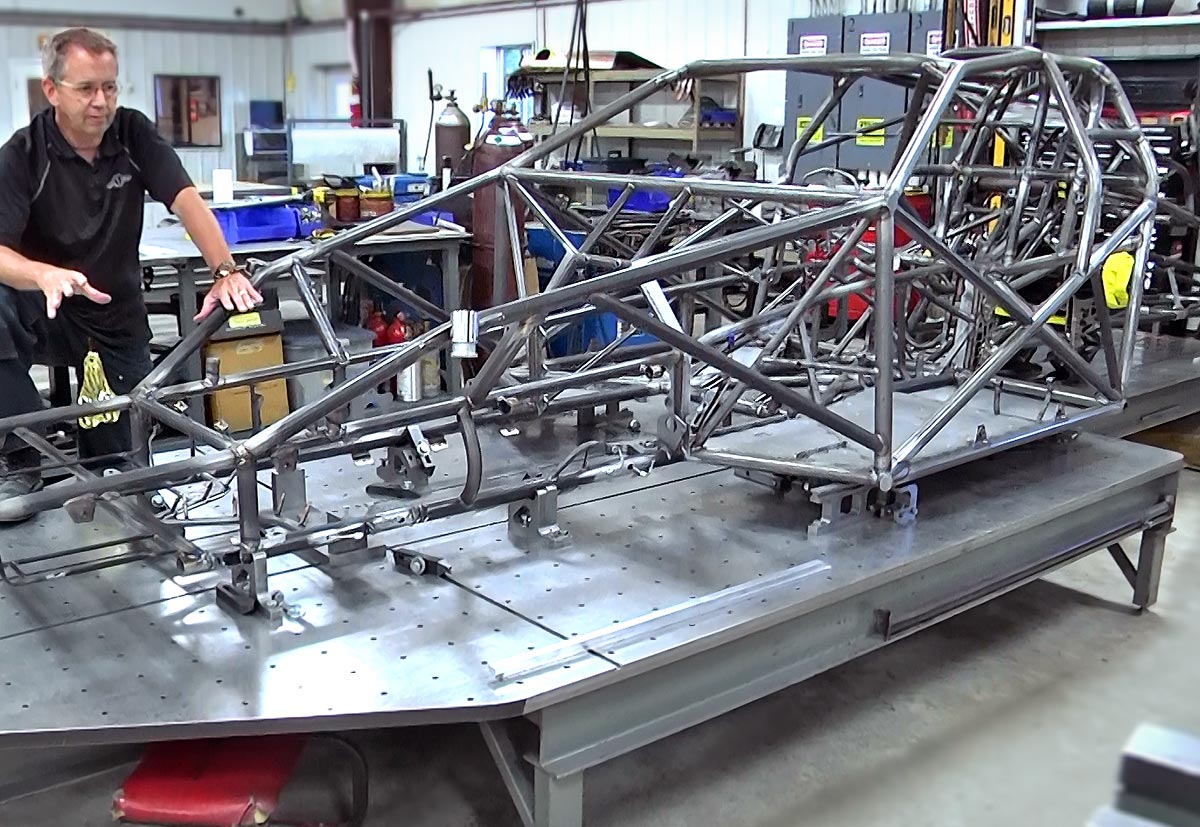

Casual Info About How To Build A Chassis Jig

In this video you’ll get tim’s usual simple and straightforward approach, and learn how you too can put something together to build your own chassis at home.

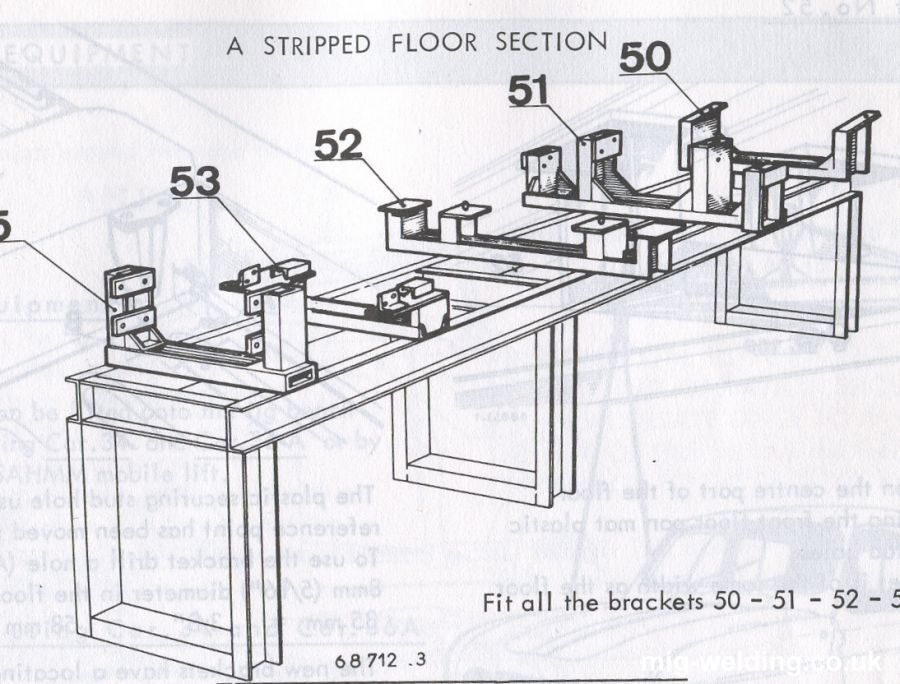

How to build a chassis jig. #3 · nov 19, 2018. First pic is set up for subframes. One way to build a chassis jig is to weld a frame out of square tubing.

This frame can be made as simple or as complex as needed, but it needs to be able to support the chassis. To just build one chassis use some graph paper to draw up your chassis and then transfer it to a pice of mdf and simply drill some holes or even drive in some nails. Cnc machined for perfect alignment of all the chassis parts in your kit.

We then squared up the beams and used the eastwood mig 250 to tack weld them together. Put the car in the jig with the tires in the big c channels. If everything is cut to the right size, assembly simply becomes a game of putting everything in.

#mustangbodyjig #mustangchassisjig #classicmustang this video is part 1 in a series of video i am doing on designing & building a body jig for a classic ford. With a jig, the parts in a fabrication are held rigidly in the correct location. “you can build a jig with materials from a scrap yard by making two parallel rails leveled off a garage floor.

Pics of what i built are below. Level it, cut frame, intstall new subframe withe the wheels/tires and weld away. Additionally, you’ll discover just how easy and affordable it is to do on your own.

Before we can start on the build of our tube chassis buick regal, we need a level place to work, so today i'm going to show you how to make your own chassis. Didn't cost much at all and i set it up for my exact car. That is for the roadsters, altered, and dragsters.